service

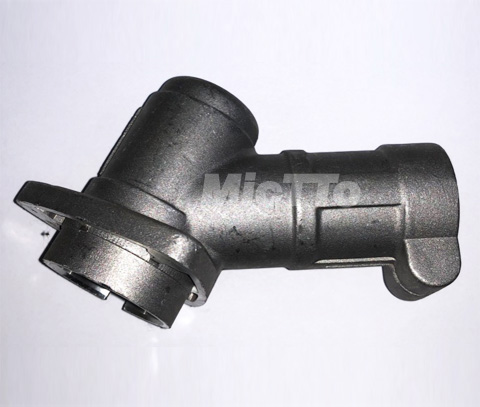

Customer:Zhejiang grass cutter housing machining enterprise

Equipment:Domestic

Chuck:AC225C

This customer is Zhejiang grass cutter housing machining enterprise. The two ends of the housing are 120 degrees, and the angle tolerance of the two ends is required to be ±5'. It is not only difficult to design fixture but also difficult to ensure the dimension by using the original sequential machining technology. This customer found Mictto through similar products on display at the exhibition. Through Mictto chuck, the machining of the product can be completed at one time, which completely solves the problem that the machining angle of the product is hard to control. At the same time, the indexing chuck realizes one person operating three equipments, which saves one third of the labor cost compared with original.

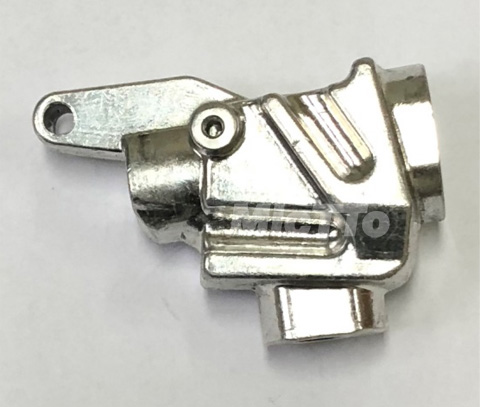

Customer:Zhejiang gas gun housing machining enterprise

Equipment:Domestic

Chuck:Non-standard AC168A

This customer is an enterprise specializing in machining air gun housing in Zhejiang. Originally, the customer needed three machines to machine the product in three steps. Because the customer's product angle is non-standard, Mictto developed a non-standard indexing chuck for the customer to meet the customer's three-end machining requirements, through the indexing chuck to complete the machining of this product at one time. At the same time, combined with the beam manipulator, the customer realized the goal of one person operating six equipments, and successfully reduced the number of personnel of the product to one third of the original.

Customer:Zhejiang well-known air conditioning pipeline enterprise

Equipment:Domestic

Chuck:AC168A

This customer is Zhejiang well-known air conditioning pipeline machining enterprise. The customer‘s machining of this product was originally divided into three steps of turning and punching,etc. The customer uses equipment with power head and indexing chuck to complete all processes at one time. Through this change, customers have realized the transformation from one person controlling two machines to four. While the number of workers on the site is reduced by half, the production output on the site is also increased, and the space on the site is saved.

Customer:Zhejiang famous water meter enterprise

Equipment:Domestic

Chuck:AC256A、AC305A

This customer is a famous water meter enterprise in Zhejiang. Water meter products from the customer are exported to Japan and the United States. This customer has been using our chucks since 2014. The customer started with trial one set, then 3 groups of units (9 sets). Now all related products on site are machined by indexing chucks. There are more than 60 indexing chucks from our company. To quote the customer boss' original words, "After using our indexing chuck, the machining cost of a product has dropped from 0.92 yuan to 0.37 yuan.” The machining cost has been greatly reduced. In order to match the indexing chuck project, the customer rejected the imported special equipment (Special machine, slow model changing, machining precision can not meet the requirements) and added the same number of CNC lathes.

Customer:Domestic pump housing supplier of Grundfos

Equipment:Imported

Chuck:AC225A、AC256A、AC305A

The customer is the domestic supplier of Grandford,the world's first brand of high-pressure pumps. Because the machining of pump housing was originally divided into four steps.There are too many steps, the output is low, and the quality is difficult to control. The customer integrates the working steps into one step with indexing chuck+ Turning-Milling equipment +joint robot, completes all the working steps of the housing and loading and unloading at one time, and realizes 24-hour non-stop machining of the housing. At present, there are two automatic production lines of pump housing on customer site, which can completely replace the production capacity of more than 10 original equipments. At the same time, the number of operators is one-third of the previous number.